Available in: |

Xpress |

Standard |

Expert |

Professional |

Premium |

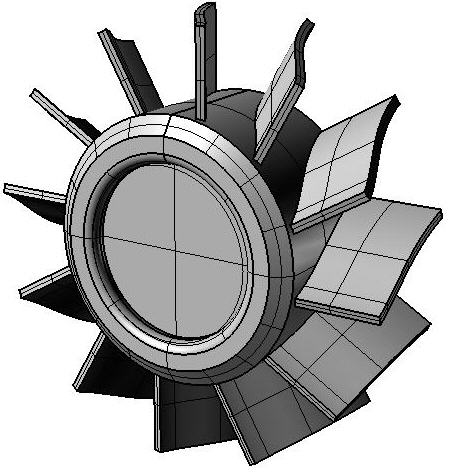

![]() 5 axis simultaneous machining can be used to machine parts such as aerospace wing components, impellers, manufacture of cutting tools, trimming of blow molds, sheet metal dies and is also popular in the woodworking and plastic industries.

5 axis simultaneous machining can be used to machine parts such as aerospace wing components, impellers, manufacture of cutting tools, trimming of blow molds, sheet metal dies and is also popular in the woodworking and plastic industries.

|

The part shown below is a design of an impeller. In this mode, tool path orientation is determined by surface normal direction. This type of machining is called simultaneous 5 axis machining and can be employed to efficiently machine such parts. 5 axis operations are local operations. It is not recommended to create toolpaths on the entire part. Some areas of your part are suitable for 5 axis machining. Such areas must be selected and you must clearly define the strategy to get a good tool path result. This is very different that typical 3 axis global operations, where you calculate roughing or finishing using all surfaces.  Indexed 5th Axis Machining Operations |

In 5 Axis operations, the role of Part surfaces is non-existent. You can define only Drive and Check surfaces. The Drive surfaces determine the tool location and tool axis in some cases while the Check surfaces define the surfaces to avoid. Drive surface is the model geometry which is used for tool path generation; it is the surface you want to work on and defines the shape to be milled. You can select multi surfaces.

|