Available in: |

Xpress |

Standard |

Expert |

Professional |

Premium |

![]() Fifth axis machining enables you to change tool direction relative to any set of axes. Fifth Axis operations are used to machine parts that cannot be machined with 2½, 3 and 4 axis machining operations. Since the tool moves only up and down along the Z axis during 3-Axis milling, areas that cannot be seen from above cannot be cut. In such cases, the object could be divided into multiple sections and machined separately. MILL module’s implementation of simultaneous and indexed fifth axis milling allows you to do this automatically if the machine tool is equipped with a head/head, table/head or a table/table configuration. Indexing refers to the ability of rotating the head/head or the table/head on the machine tool and then performing machining in a 3 Axis fashion with the part locked at its orientation.

Fifth axis machining enables you to change tool direction relative to any set of axes. Fifth Axis operations are used to machine parts that cannot be machined with 2½, 3 and 4 axis machining operations. Since the tool moves only up and down along the Z axis during 3-Axis milling, areas that cannot be seen from above cannot be cut. In such cases, the object could be divided into multiple sections and machined separately. MILL module’s implementation of simultaneous and indexed fifth axis milling allows you to do this automatically if the machine tool is equipped with a head/head, table/head or a table/table configuration. Indexing refers to the ability of rotating the head/head or the table/head on the machine tool and then performing machining in a 3 Axis fashion with the part locked at its orientation.

This type of programming allows the machining of part geometry that has more than one side that needs to be machined. Using an indexing head as the one shown will allow easy reorienting of machine tool. Note that in order to utilize 5 axis indexing you must have a CNC control that supports a fifth axis that can be controlled by the CNC machine.

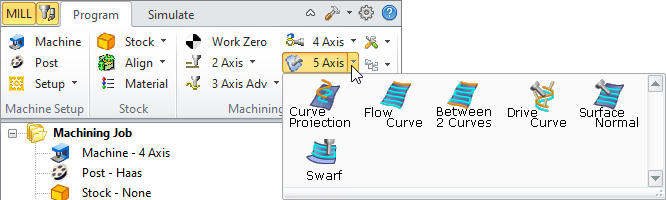

5 Axis Operations Menu - Premium Configuration Shown

|