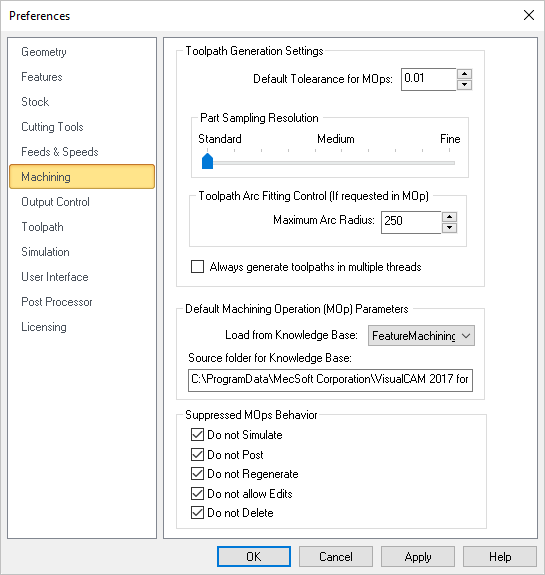

You can set the machining preferences using this dialog.

CAM Preferences: Machining |

Default Tolerance for Mops Enter the default tolerance to use for new machining operations. You can edit this parameter manually from the Cut Parameters tab of each machining operation (Mop) dialog. Part Sampling Resolution This slider is used to control the display quality of the simulated model. Standard is faster but with lower display quality. For large parts, use the Standard or Medium options, while for smaller parts Medium or Fine options would work satisfactorily. Toolpath Arc Fitting Control (If requested in Mop) Some toolpath operations support Arc Fitting. If supported, the option is located on the Advanced Cut Parameters tab of the operation's dialog. Maximum Arc Radius Some toolpath operations support Arc Fitting. You can enter here the Maximum Arc Radius that can be created. Always generate toolpath in multiple threads Check this box to Always generate toolpath in multiple threads. The system will distribute the computing of multiple toolpaths to different cores in your processor simultaneously rather than sequentially. Refer to Multi-threading Manager section for additional information. |

Load from Knowledge Base This allows you to select a Default Knowledge Base to load for creating machining operations. Selecting a knowledge base as Default loads the operation parameters when creating new operations. If no Default knowledge base is specified, the system defaults are used for machining operation parameters. Source Folder for Knowledge Base This is the source folder where the Default Knowledge Base are stored. |

When you Suppress Machining Operations (Mops) you can apply one or more of these conditions. Check each box to enable that condition and then pick OK to close this dialog. |