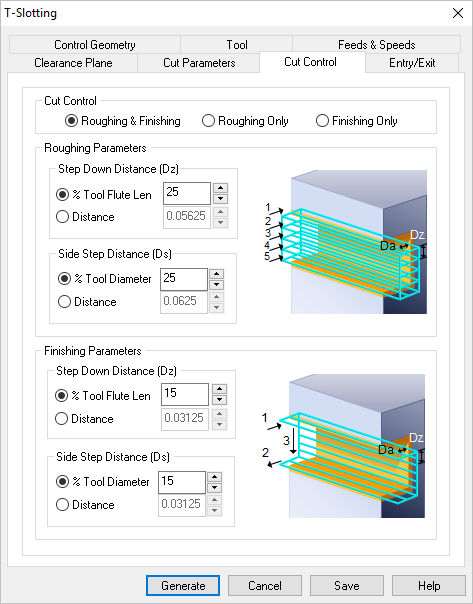

The following Cut Control tab allows you to define the Roughing and Finishing parameters for the current 2½ Axis T-Slotting operation. You can set Step Down and Side Step parameters for both Roughing and Finishing moves. The roughing passes are similar to profile operation. Refer to each option below.

Dialog Box: Cut Control tab, 2½ Axis T-Slotting Operations |

This section allows you to select between Roughing Only, Finishing Only or Roughing & Finishing passes. |

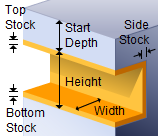

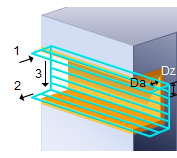

These two sections allow you to Step Down and Side Step Distance. Step Down Distance (Dz) This is the amount the cutter moves for each cut in Z. Note that the total cut depth is defined by the slot definition. User can define the step as a % Flute Length or as Distance. The algorithm will create a cut at top and bottom and if there is any space in between, additional cut levels will be created. Side Step Distance (Ds) This is the amount the cutter moves on the side to cut the slot. This will allow the cutter to make a pre-cutting pass before engaging into material. It can specified as a % Tool Diameter or a Distance. Finishing Passes Allows you to specify Step Down and Side Step Distance. The Step Down Distance (Dz) and Side Step Distance (Ds) parameters are set similar to roughing parameters. In the finishing pass, the cutter will remove the Top stock first and then remove the bottom stock next in such a way that it leaves uniform side stock. Then it will perform the Z passes from top to bottom to remove the final side stock, starting from top to bottom.

|