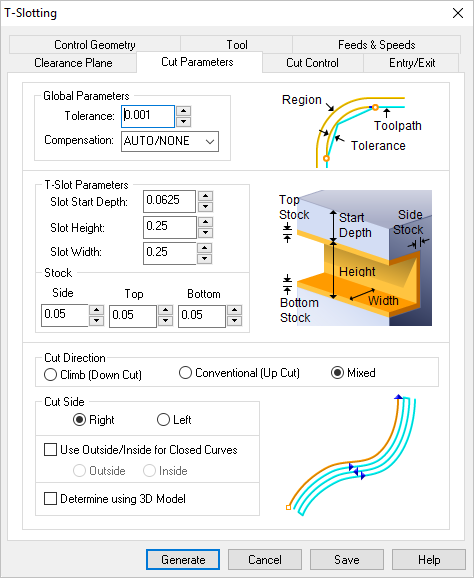

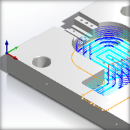

The following Cut Parameters tab allows you to define the parameters for the current 2½ Axis T-Slotting operation. In this method, you do not need to model the T-Slot on the part geometry. The top of the slot is modeled and picked as a Machining Feature/Region.

You can set Global Parameters, T-Slot Parameters, Cut Direction and the Cut Side via this tab of the operation dialog. The Global Parameters section allows you to set the tolerance value to be used in machining. Refer to each option below.

Dialog Box: Cut Parameters tab, 2½ Axis T-Slotting Operations |

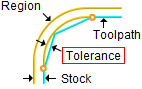

The Global Parameters section allows you to set the tolerance value to be used in machining. A uniform thickness or stock that needs to be left around the part can be specified here. Tolerance This is the allowable deviation from the actual part geometry plus the Stock allowance (if any). In 2 Axis methods, this Tolerance is applied to XY motions only.  Tolerance

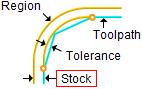

Stock This is the thickness of the layer that will remain on top of the part after the toolpath is complete. Roughing operations generally leave a thin layer of stock. For finishing operations this value is zero.  Stock Compensation This enables cutter compensation. The compensation direction, left or right, is determined by the Cut Direction selected (Climb or Conventional). |

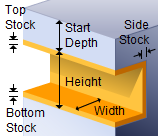

T-Slot Parameters, 2½ Axis This section allows you to set the slot depth, width and stock to leave. Enter the following values: Slot Start Depth Slot Height Slot Width Stock |

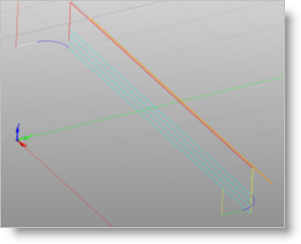

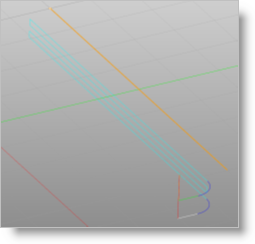

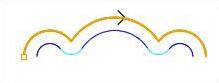

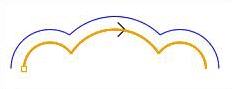

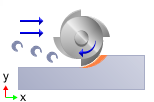

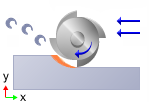

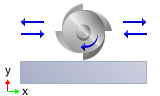

Climb (Down Cut) Select Climb (Down Cut) and the tool will be maintained in a downward motion into the stock.  Climb (Down Cut) Conventional (Up Cut) Select Conventional (Up Cut) and the direction of the tool will be maintained in an upward motion out of the stock.  Conventional (Up Cut) Mixed Select Mixed and the direction of cutting is alternated between each parallel plane. This is a mixture of both Climb and Conventional cutting of the stock.  Mixed

For Z Level Cuts When Mixed is selected, zigzag motions are applied between step downs to eliminate tool retracts between z levels. If Climb or Conventional is selected, retract between z levels are applied. Refer to the images below:

|

This determines the side of the curve to be cut. Right / Left

Use Outside or Inside for Closed Curves Determine using the 3D model Note: This feature is not available in Xpress configuration.

|

One of the basic concepts to understand in any milling operation is

One of the basic concepts to understand in any milling operation is