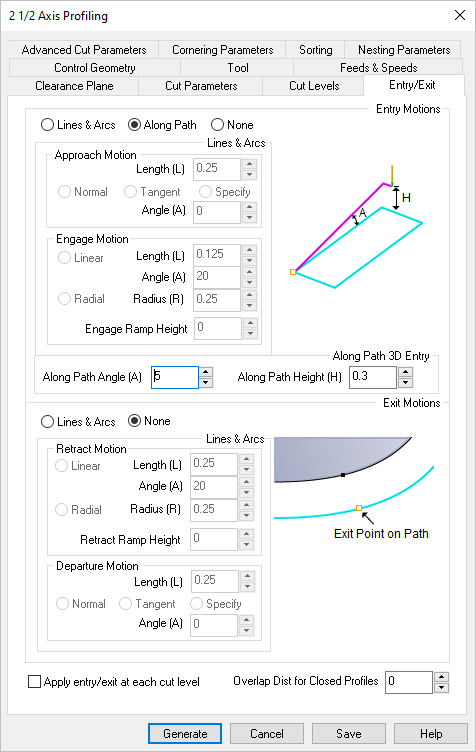

The following Entry/Exit tab is similar for the Mill operations listed below. Entry and Exit determines the way in which tool enters and leaves the part geometry. MILL Module allows you to specify how the cutter approaches, engages, retracts and departs when starting and stopping a cut.

Facing, 2½ Axis Profiling, 2½ Axis Chamfering, 2½ Axis Filleting 2½ Axis T-Slotting, 2½ Axis Re-Machining, 2½ Axis Facing, 4 Axis Profiling, 4 Axis |

Dialog Box: Entry/Exit tab, 2½ Axis Milling operations |

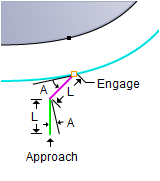

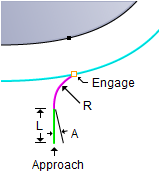

You can set different feeds for plunge, approach, engage, cut, retract and depart moves. The tool moves to the position above the approach point with a plunge feed, then uses the approach feed rate for the vertical approach motion and engage feed rate for the engage motion. Lines & Arcs This is a 2D entry motion consisting of an Approach Motion and an Engage Motion. For the Approach Motion, enter the approach Length (L). Then, depending on the stock material and cut pattern select the approach angle as either Normal, Tangent or Specify Angle (A) with respect to the stock. For the Engage Motion select Linear or Radial. In the Linear motion the cutter follows a linear ramp motion, Ramping back and forth from a user specified height to the engage point. The Length (L) of this move, as well as the Angle (A) of this motion can be specified.

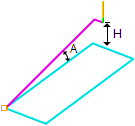

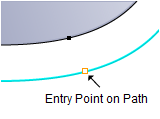

Along Path The Entry path can be defined as a 3D Entry along a specified Along Path Angle (A) with a Along Path Height (H). Ramp height is set automatically between cut levels if you set a ramp height smaller than the height from the previous level to the current level.  Along Path None No entry motion is defined for the current operation.  None |

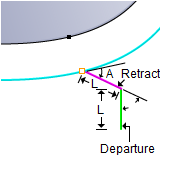

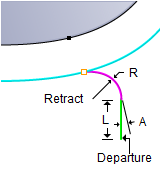

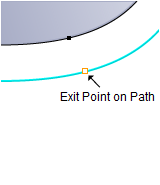

The Exit motion consists of a Retract Motion followed by a Departure Motion. The departure motion is a linear motion. Lines & Arcs

For the Departure Motion, enter the departure Length (L). Then, depending on the stock material and cut pattern select the departure angle as either Normal, Tangent or Specify Angle (A) with respect to the stock. None  None |

Check this box to apply the Entry/Exit Motions to each cut level. |

This option allows you to specify an overlap distance for closed profiles to avoid leaving small tool marks at the start point of the part. The toolpath will start as specified, follow the closed profile back to the start point and then continue past for the specified distance. The overlap distance will be restricted so that it cannot exceed the profile length.

|