The following Cut Levels tab is similar for the Mill operations listed below that use Features as Control Geometry. It allows you to define the Cut Depth Control and Cut Levels Ordering. Refer to each of the sections below for more information. Refer to the Features tab of the Machining Objects Browser to learn more about extracting Machining Features from your 3D part model.

Facing, 2½ Axis Pocketing, 2½ Axis Profiling, 2½ Axis Slotting, 2½ Axis |

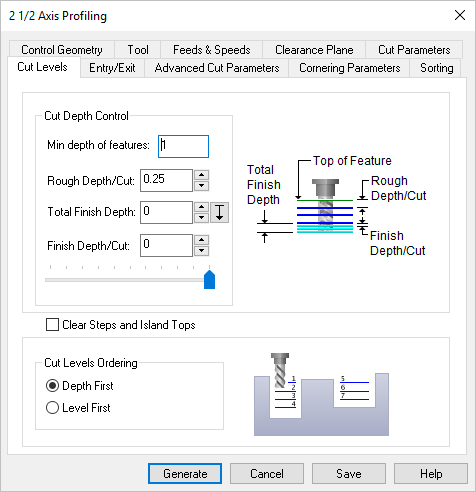

Dialog Box: Cut Levels tab, MILL Features |

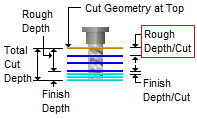

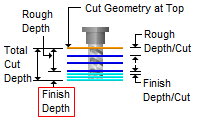

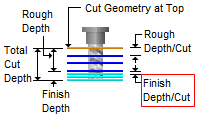

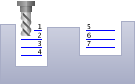

Min Feature Depth This is the minimum depth required to cut the feature. It is extracted from the Feature definition. Rough Depth/Cut The Rough Depth can be divided into a multiple depths. Enter the Rough Depth/Cut here.  Rough Depth/Cut Total Finish Depth The Total Cut Depth can be divided into a Rough Depth and a Finish Depth. Enter the Finish Depth here. Refer to the illustration below for reference.  Finish Depth Finish Depth/Cut The Finish Depth can also be divided into a multiple depths. Enter the Finish Depth/Cut here.  Finish Depth/Cut |

Checking this box will Clear Island Tops (inner regions) and will also add a cut level at each z step in the pocket feature. |

Setting the cut traversal to Zig generates cuts along the direction of the curve, retracts the tool to cut transfer plane and starts at the same start location for the next level. Setting the cut traversal to ZigZag cuts both directions.

|

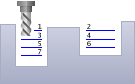

Order the Cut Levels in this operation so that the entire Z depth of each feature is machined before moving on to the next feature.  Depth First Order the Cut Levels in this operation so that all regions in a single Z level are machined first before moving on to machine the next cut level.  Levels First |