![]() In 2½ axis toolpaths, the tool can move in X and Y directions, but Z movements are limited to set levels. Because 2½ axis toolpaths do not relate to either part or stock geometry, machining regions must be selected; these define the boundaries of tool motions.

In 2½ axis toolpaths, the tool can move in X and Y directions, but Z movements are limited to set levels. Because 2½ axis toolpaths do not relate to either part or stock geometry, machining regions must be selected; these define the boundaries of tool motions.

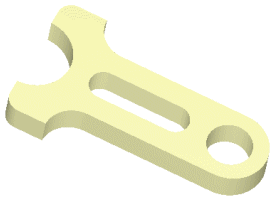

A typical machining operation would involve roughing then finishing. Unlike the more complex 3 axis parts, detailed finishing is typically not necessary for prismatic parts. Roughing is typically performed using a combination of Facing and Pocketing operations, and Profiling is used for finishing.

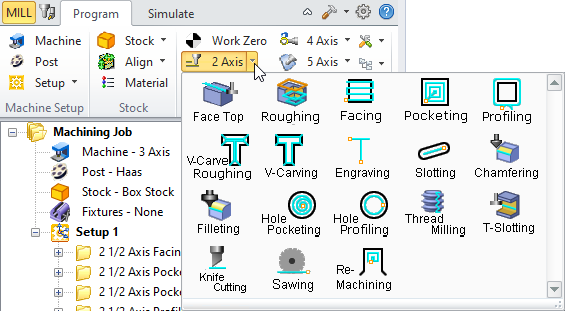

Two and a Half Axis (2½) Axis Operations Menu |

This type of machining is useful for machining prismatic parts – extrusions of curves along the Z axis. Because of its straight sides, a prismatic part can be machined by locking the tool at the first Z level, performing XY motions, then repeating for subsequent Z levels.  Prismatic Part Example |

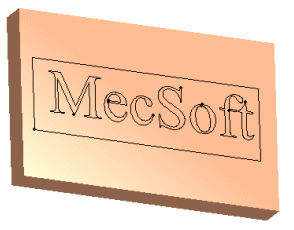

Using this class of machining, you can machine parts that are defined only by 2D curves. 3D part geometry can be present, though it is not necessary.  2D Curve Example |