Available in: |

Xpress |

Standard |

Expert |

Professional |

Premium |

![]()

Steeps (Parallel Hill) Machining, 3 Axis

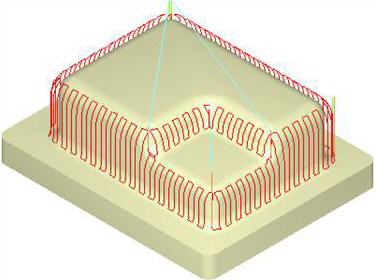

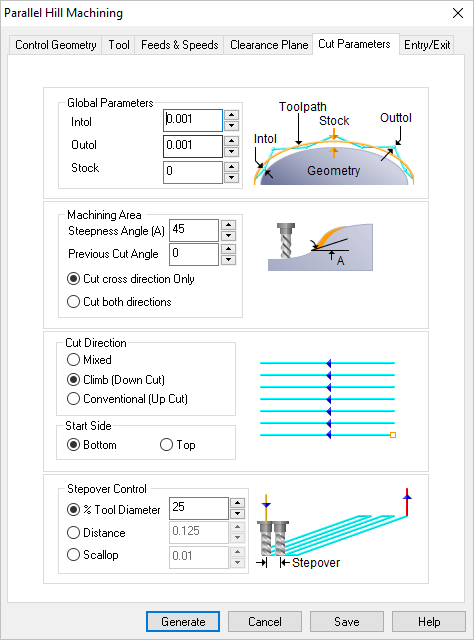

The Steeps (Parallel Hill) Machining is a toolpath which can be used as a re-finishing operation that is applied after a Parallel Finish operation. In this cut method, the cutter is restricted to machine areas in the part that are steeper than a user specified angle from the horizontal XY plane. Once the system identifies these regions then a Parallel Finish type of machining is employed to machine these regions.

Additionally the system automatically chooses between two cut angles to machine these areas so as to maintain proper scallop height control on the part. One of these two angles is the cut angle used in the previous Parallel Finish operation (this is input by you) and the other angle is 90 degrees to this angle.

Optionally, you can specify to cut only those regions that were not properly machined by the previous Parallel Finish operation. These regions would be steep areas in the part that were parallel to the cutting angle of the previous operation. In this case the toolpath will only be created in the cut direction that is 90 degrees to the previous cut angle.

See also: What Tool Types are Supported by this Operation?

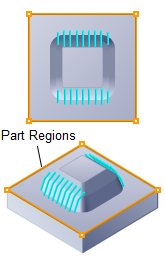

Steeps (Parallel Hill) Machining, 3 Axis Examples |

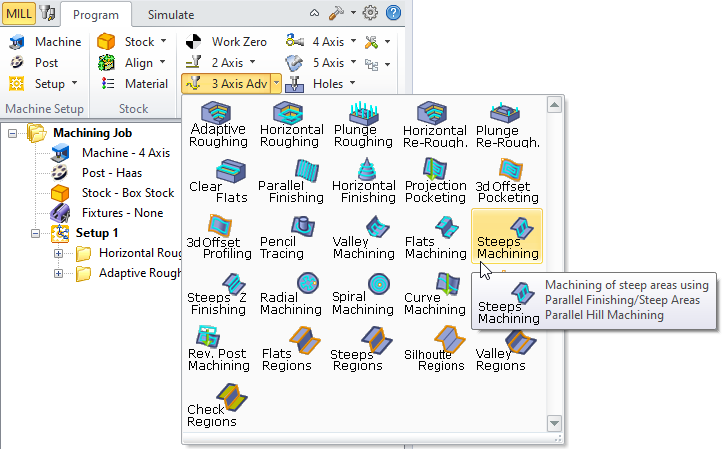

The Steeps (Parallel Hill) Machining toolpath method is invoked by selecting the Program tab, clicking on the 3 Axis Adv button in the Machining Browser and selecting the Steeps Machining Operation.  Steeps (Parallel Hill) Machining, 3 Axis Menu Item |

The dialog that is invoked when you choose this toolpath method is shown below:  Dialog Box: Steeps (Parallel Hill) Machining, 3 Axis |