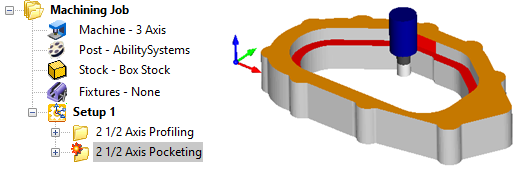

MILL module offers very powerful cut material simulation functionality to allow you to simulate actual machining of the generated toolpaths. The output of this simulation is a true 3D cut model. This 3D model can be rotated, zoomed and manipulated.

This cut model can be visually compared with the part model to show areas of uncut material and/or areas of over-cut material using this component. The simulation features allow the early detection and correction of programming errors.

Note: See Right-Click Commands for a complete list of all right-click commands available from the Machining Operations (Mops) Browser and the Machining Objects (Mobs) Browser.

There are three kinds of toolpath simulation available in MILL module. These are The simulation can be performed either on the currently active machining operation or on multiple operations. |

If a tool holder collision occurs during the simulation, the affected machining operation is immediately flagged as dirty.  Tool Holder Collisions |

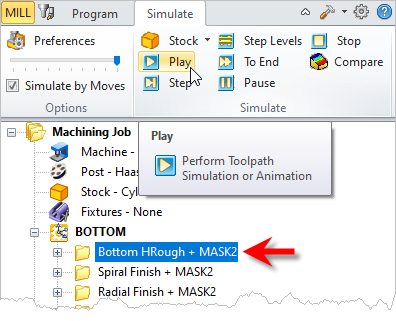

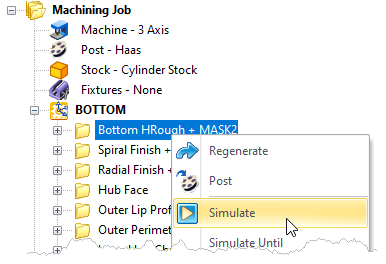

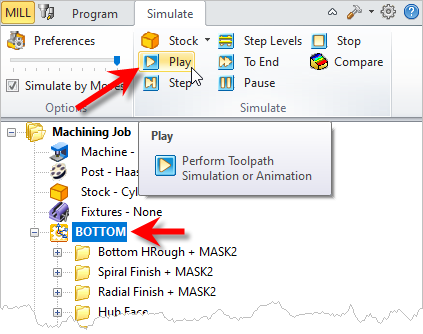

The active operation is the one that is selected and shown highlighted in the Machining Browser. Typically, this would be the last toolpath that was generated. To simulate any operation, select the operation in the browser and click Simulate from simulate tab of the browser or by using right click and Simulate.  Simulate the Active Operation  Simulate the Active Operation |

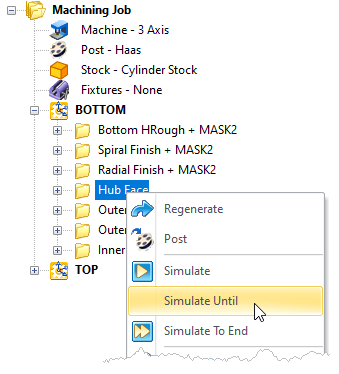

To perform simulation on multiple operations select the last operation, right click and choose Simulate Until. You can also select multiple operations by holding down the Ctrl key.  Simulate Until the Active Operation |

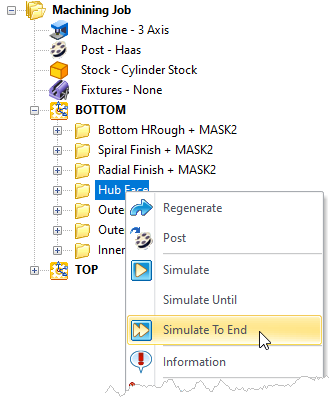

To simulate directly to the end of the Machining Job, right click on any operation and select Simulate to End.  Simulate to End |

Alternatively you can select a Setup and select Simulate to simulate all the operations within a Setup.  Simulate all Operations within Active Setup  Simulate all Operations within Active Setup |