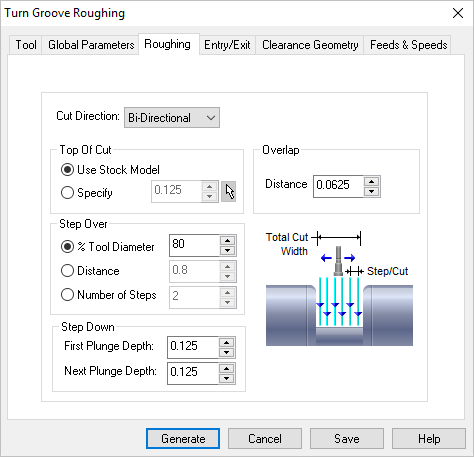

In this tab, parameters like the Cut Direction, Step Over and Step Down can be specified for Turn Groove Roughing operations.

Dialog Box: Roughing tab, Turn Groove Roughing |

This can be either Bi-Direction or Uni-Directional. Bi-Directional cuts start at the center of the groove and works its way in both directions towards the start and end points. Uni-Directional cuts start from the start point and works its way towards the end point of the groove feature. When using Bi-Directional, an Overlap distance parameter can be specified.

|

This tells the system where to begin cutting. Select Use Stock Model to allow the system to determine this location based on the Stock. Select Specify and then enter a value to locate where to begin cutting.

|

With Cut Direction set to Bi-Directional, you can also specify an Overlap Distance. Enter a value in the Distance field. |

This allows you to specify the spacing between groove cuts. You can set this to one of the following: % Tool Diameter: Enter the percentage of the groove tool to use. Distance: Enter the step over distance. Number of Steps: Enter the total number of steps to use. |

This allows you to define the depth between the cut levels for the roughing operation. You can specify the First Plunge Depth and the Next Plunge Depth for subsequent levels. These are set as a specified distance. |