![]()

Groove Roughing

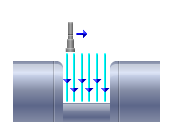

This operation is performed to machine grooves in multiple cuts on the part. This roughing operation provides user the control to set the step down and step over and choose the cut direction.

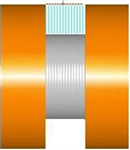

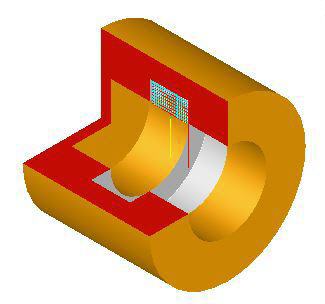

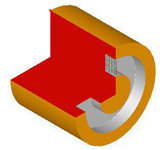

Both part and stock geometry are used to determine the regions that can be safely machined. Groove Roughing can be of 3 types: OD Groove Roughing, ID Groove Roughing, and Face Groove Roughing. The grooves are typically used to slide/fit one part into another to obtain the required assembly.

|

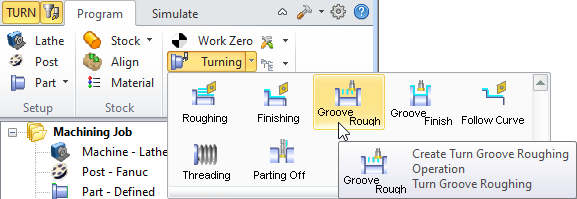

The Groove Roughing toolpath method is invoked by selecting the Program tab, clicking on the Turning button in the Machining Browser and selecting the Groove Roughing operation.  Turn Groove Roughing Menu Item |

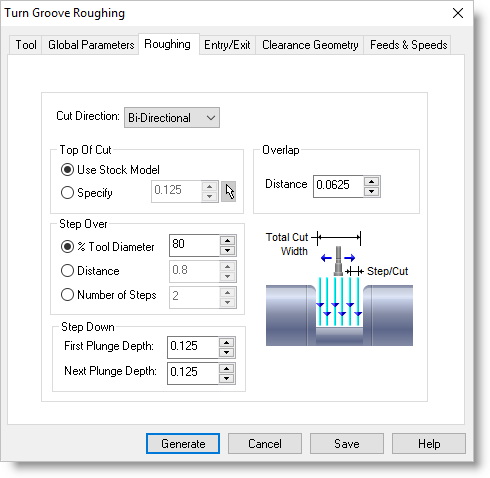

This section describes the various parameters that you can set to execute this machining operation. The dialog that is invoked when you choose this toolpath method is shown below: This dialog has six tabs. Each tab defines a set of parameters that you can specify. The sections below describe them in detail.  Dialog Box: Turn Groove Roughing |