Available in: |

Xpress |

Standard |

Expert |

Professional |

Premium |

![]()

Profiling, 2½ Axis

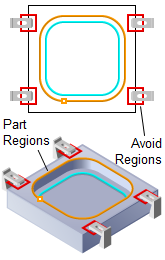

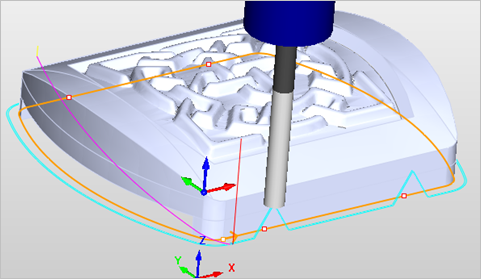

2½ Axis Profiling is a toolpath method that employs regions and can be used either as a pre-finishing operation or as a finishing operation. These regions are treated as the tops of vertical walls spanning from the Z values of the regions down to your specified minimum Z.

This method is similar to Horizontal Finishing except that the system does not consider the part geometry during computation. As in Horizontal Finishing, the cutter finishes in constant Z planes. The tool types commonly used in this method are Flat End Mills.

As the cutter follows these horizontal planes, it can either maintain climb/conventional/mixed type of machining. In climb or conventional, the direction of cutting is maintained so as the corresponding cutting condition is maintained on the part. In the mixed type of machining however, the direction of cutting is alternated between each parallel plane.

See also: What Tool Types are Supported by this Operation?

2½ Axis Profiling |

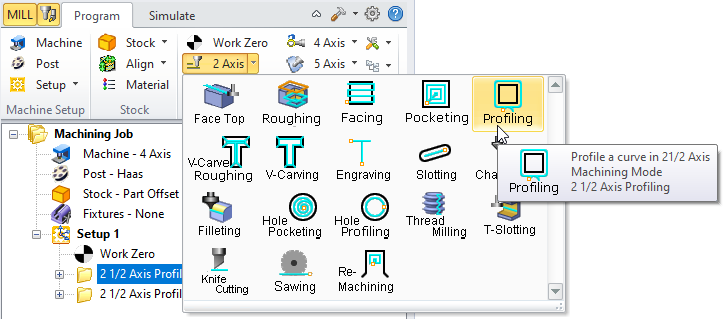

The Profiling toolpath method is invoked by selecting the Program tab, clicking on the 2½ Axis button in the Machining Browser and selecting the Profiling Operation.  2½ Axis Profiling Menu Item |

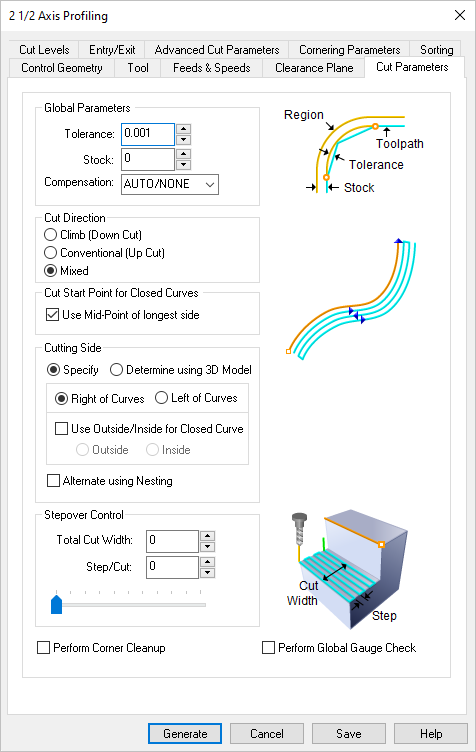

This section describes the various parameters that you can set to execute this machining operation. The dialog that is invoked when you choose this toolpath method is shown below:  Dialog Box: 2½ Axis Profiling |