Facing and pocket machining are very similar methods of machining 2-D geometry. Both are area clear operations in that they both remove material over an area. However, the principal difference between these two operations is that the way the methods treat the outermost region of the selected region geometry.

Facing considers all outermost regions as the boundaries of stock geometry, that is, the limits of the material to be machined away. All internal regions are considered as part geometry, that is, geometry that cannot be cut. |

Pocketing, on the other hand, considers all regions as part geometry or geometry that cannot be cut. This difference in interpretation of the region geometry's purpose causes a significant difference in the tool's cut pattern during machining. The table below illustrates the cut pattern generated in both of these operations for identical region geometry. |

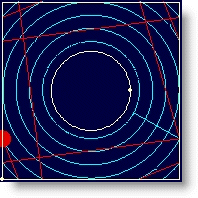

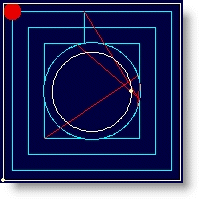

In the toolpath comparison below, notice that in the facing operation, the cutter (represented by the red filled circle) travels from the outside to the inside, treating the outside region as material to be cut away. In the pocketing operation, the cutter treats the outside region as a wall and stays tangent to it. Notice also the significant differences in the cut patterns for both of these operations.

|