Cutter Compensation is used typically to compensate for the difference in the dimensions of the actual cutter used in machining and the cutter used for programming in MILL module. For example, if the cutter used in programming in MILL module is 0.25 inches and due to tool wear the actual cutter is only 0.24 inches in size, you can compensate for this in the controller rather than having to re-program the operation again. Refer to the 2½ Axis Control Matrix for information about which toolpath operations support Cutter Compensation.

To do this you need to do the following: 1.Turn cutter compensation on in the Operation Set Compensation to Auto/ON or Control/ON. 2.Specify the cutter compensation value and the compensation register in the controller (the controller needs to be capable of doing this) |

|

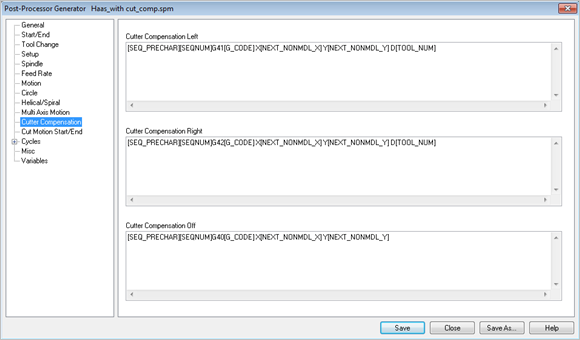

Select the Post Processor from the Setup tab in Machining Browser by selecting Utilities and Post Processor generator.  Post Processor generator |