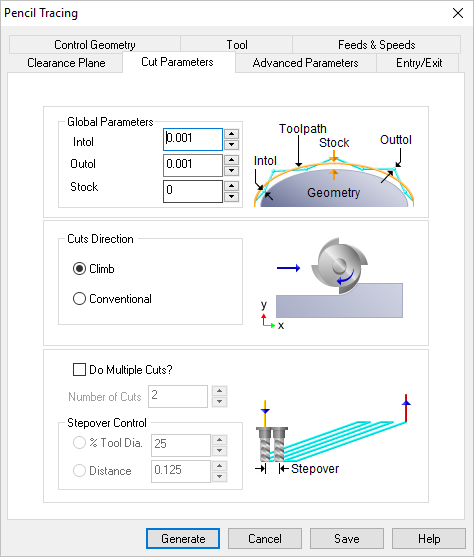

The following Cut Parameters tab allows you to define the cut parameters for the current 3 Axis Pencil Tracing operation. You can set Global Parameters, Cut Direction and the Stepover Control via this tab of the operation dialog. The Global Parameters section allows you to set the tolerance value to be used in machining. A uniform thickness or stock that needs to be left around the part can also be specified here. Refer to each option below.

Dialog Box: Cut Parameters tab, Pencil Tracing, 3 Axis |

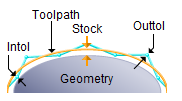

Global Parameters, 3 Axis Operations The Global Parameters section allows you to set the tolerance value to be used in machining. Intol and Outol are allowable deviations (tolerances) from the actual part geometry plus the Stock layer (if any). A uniform thickness or stock that needs to be left around the part can be specified here. Intol / Outol

Stock |

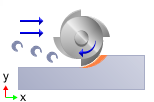

The Cut Direction of the toolpath can be specified either as Climb or Conventional by selecting the appropriate radio buttons. As mentioned before, in climb or conventional, the direction of cutting is maintained so as the corresponding cutting condition is maintained on the part.

|

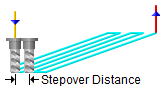

This allows you to have 2 or more cut passes and the distance between the cuts can be specified using Stepover Control (see below). Specifying the Number of cuts = 2 results in 2 cuts on both sides of the pencil trace.

|

Stepover Control, 3 Axis Operations This allows you to define the spacing between the cuts. Select from the following options: % Tool Diameter Distance Scallop (not available for all operations) |

One of the basic concepts to understand in any milling operation is

One of the basic concepts to understand in any milling operation is