The following dialog allows you to set the Cut Parameters for Tapping operations. You can set the Tap Type, Depth Control, Location, Dwell and other parameters via this dialog box.

Dialog Box: Cut Parameters tab, Tapping, 2½ & 4 Axis |

The tap cycles supported are:

|

||||

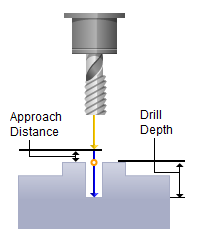

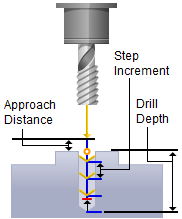

Refers to the tap depth. |

Select from the following for Location of Drill Point(s): At Top This uses the Z location of the selected Control Geometry as the top of cut. The generated cuts will start at this Z location and cut down in Z to the specified total Drill Depth. At Top is typically used when your hole diameters or drill points are at the top of your part. At Bottom This uses the Z location of the selected Control Geometry as the bottom of cut. The generated cuts will be above the selected machining region and last cut would be at the Z location of the specified region. At Bottom is typically used when you select the diameter or drill points are at the bottom of the hole. Project to 3D Model This option projects the selected the Control Geometry to the underlying 3D geometry. Pick

|

Dwell is an optional parameter that allows a machine delay of either Time (sec) Rev (rpm) of the spindle. |

You can define the Approach Distance under Engage/Retract. The tool rapids in Z axis to the approach plane and applies the specified feedrate from the approach plane to the specified depth to perform the cycle. |

Allows you to select between Clockwise and Counter Clockwise tap. Selecting Right Hand Tapping creates a clockwise tap and Left Hand Tapping creates a counter clockwise tap cycle. |

This is used to set the peck depth increment. This needs to be specified for Peck Tapping. The tool retracts after each increment completely to clean out all the chips. Note that the Peck Taping cycle (G84 right-hand, and G74 left hand) needs to be defined in your post-processor. |