The following dialog allows you to set Turn Roughing parameters. In this tab, parameters like the Cut Pattern Type, Cut Pattern Direction and the Depth per cut can be specified.

Dialog Box: Turn Roughing tab, Turn Roughing operations |

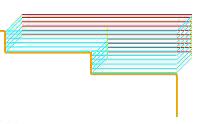

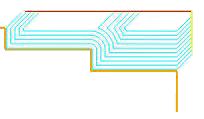

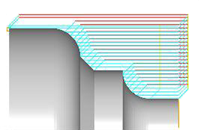

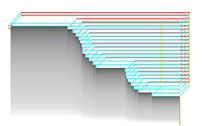

This defines the type of path that the tool will follow at each cut level. You can choose a linear cut pattern where the tool will always traverse in linear cuts or an Offset cut pattern where the tool will traverse in successive uniform offsets of the part shape.

|

This can be specified as Positive, Negative or ZigZag. |

This adds a finish pass at the end of the roughing passes.

|

The top value for the cut can be either specified or determined using the internal algorithms of TURN Module. |

The depth per cut can be either specified as the actual depth per cut or as the number of passes required to remove the stock material to manufacture the final part. |