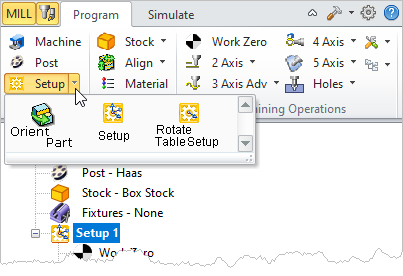

Once part geometry is loaded, you can set the cutting direction. This allows the part to be oriented in the same way as it would be fixtured on the machine tool for cutting. By default Setup 1 is created when a new part is loaded. The Setup cannot be edited in Standard and Expert configurations.

Once part geometry is loaded, you can set the cutting direction. This allows the part to be oriented in the same way as it would be fixtured on the machine tool for cutting. By default Setup 1 is created when a new part is loaded. The Setup cannot be edited in Standard and Expert configurations.

When learning any CAM software, there are many fundamental concepts you need to understand. The most basic of these are the different CAM Coordinate Systems in play, how they relate to each other and to the Machine Tool you are using on the shop floor. When learning any CAM software, there are many fundamental concepts you need to understand. The most basic of these are the different CAM Coordinate Systems in play, how they relate to each other and to the Machine Tool you are using on the shop floor.

Read the full article...

|

The Setup options are located from the Program tab under the Machining Browser. The options available will depend on your product configuration. See Setup Menu by Product Configuration below.

Machining Browser: Setup menu item |

Summary

|

Available Configuration

|

Xpress

(XPR)

|

Standard

(STD)

|

Expert

(EXP)

|

Professional

(PRO)

|

Premium

(PRE)

|

Setup Menu by Product Configuration

|

|

|

|

|

|

|

|

This allows you to orient the part to have it aligned parallel to World Coordinate System (WCS).

|

|

|

|

|

|

|

|

This is used to reorient or set the additional orientations of the machine co-ordinate system for programming parts using indexed 5 axis operations also known as 3+2 machining. This option is available in Professional and Premium configurations.

|

|

|

|

|

|

|

|

This is used to create a table rotate operation for programming parts using index 4 axis operations and is available in Expert, Professional and Premium configurations.

|

|

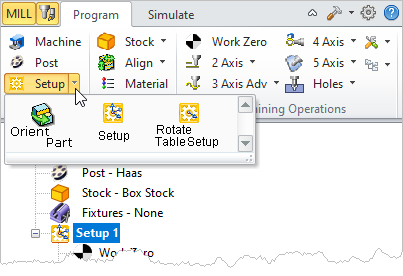

![]() Once part geometry is loaded, you can set the cutting direction. This allows the part to be oriented in the same way as it would be fixtured on the machine tool for cutting. By default Setup 1 is created when a new part is loaded. The Setup cannot be edited in Standard and Expert configurations.

Once part geometry is loaded, you can set the cutting direction. This allows the part to be oriented in the same way as it would be fixtured on the machine tool for cutting. By default Setup 1 is created when a new part is loaded. The Setup cannot be edited in Standard and Expert configurations.

When learning any CAM software, there are many fundamental concepts you need to understand. The most basic of these are the different

When learning any CAM software, there are many fundamental concepts you need to understand. The most basic of these are the different