Once the part is loaded, the typical work flow is reflected in the layout of the tabs of the Machining Browser window. The work flow is designed to allow you to work starting from the left most tab and ending at the right most tab. As each tab is accessed, a ribbon toolbar with functions specific to the tab chosen will be displayed just below the tab. The functions in each of the toolbars corresponding to each tab are also best accessed in order from left to right.

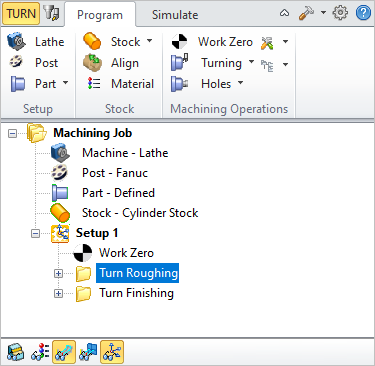

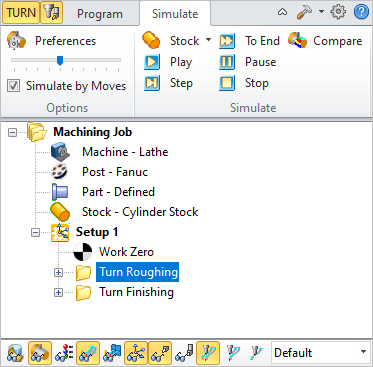

Thus you typically would start with the Program tab and access each of the buttons, optionally, in the toolbar that appears when this tab is selected in sequence from left to right. Once the setup functions are completed, you will then proceed to the Machining Operations group to commence programming the part. Once machining operations are completed you can simulate the operations by selecting the Simulate tab before finally sending the operation codes to the machine tool.

Define Machine Setup and Stock before programming Create Machining Operations  Step 1: Program Tab |

Step 2: Simulate machining operations |