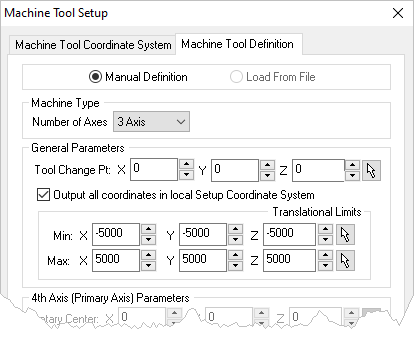

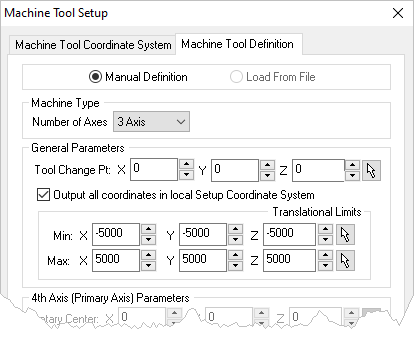

This dialog allows you to setup your Machine Tool Definition. Refer to each section below for more information.

Manual Definition

This option allows you to manually setup your Machine Tool Definition. Refer to each section below for more information.

See Load From File, Machine Tool Setup for more information.

Dialog Box: Machine Tool Setup - Manual Definition

Number of Axis

•Select 3 Axis for both 2½ and 3 Axis machining methods. |

For all Machine Types, the following General Parameters are available.

Tool Change Point

Specify the X Axis coordinate location of a Tool Change Point or use the Pick button to select a point from your 3D model. This coordinate location will be output prior to every tool change. Note: Tool change variables may need to configured in your selected Post Processor. Specify the X Axis coordinate location of a Tool Change Point or use the Pick button to select a point from your 3D model. This coordinate location will be output prior to every tool change. Note: Tool change variables may need to configured in your selected Post Processor.

Output all coordinates in local Setup Coordinate System

Check this box to output the G code's tool motion coordinates in the local setup Machine Coordinate System (MCS). If left unchecked all coordinates will be output in the World Coordinate System (WCS). Note: Rapid motions in all indexed operations are converted to federate motions when the setup is not aligned with the machine Z. This is done only when a head configuration is defined and the option Output all coordinates in local Setup Coordinate System is NOT set.

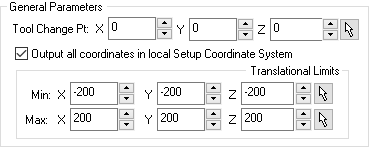

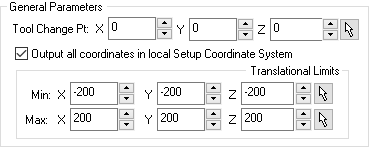

Translational Limits

This will be the Minimum X and Maximum XYZ direction Translation Limits allowed by your machine tool. Note: These parameters are not applied and are reserved for future use.

This will be the Minimum X direction Translation Limit allowed by your machine tool. Note: These parameters are not applied and are reserved for future use.

|

|