Available in: |

Xpress |

Standard |

Expert |

Professional |

Premium |

Horizontal Roughing, 3 Axis

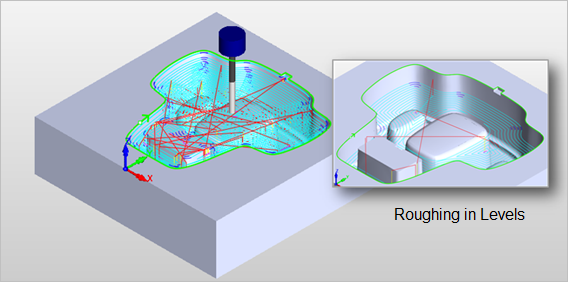

Using the Horizontal Roughing operation, bulk material is removed in layers or levels from the raw stock model. Typical tools used for this kind of operation are Flat or Corner Radius end mills. The tool starts at the top of the stock model and removes material without changing its Z position and only moving in the XY plane. Once this level is completed, then the tool moves over the next successive (lower) Z level and removes material in this XY plane.

This procedure is repeated until the bottom most Z level is reached. The spacing between cut levels can be specified. You can also specify the Z values of the top and the bottom cut levels. The method in which the tool travels in each Z level to remove material can also be controlled.

See also: What Tool Types are Supported by this Operation?

|

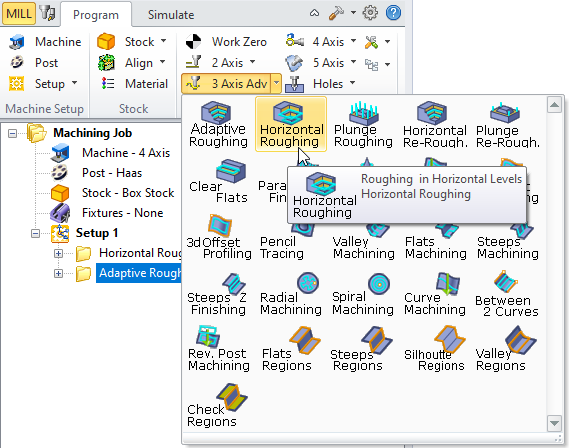

The Horizontal Roughing toolpath method is invoked by selecting the Program tab, clicking on the 3 Axis or 3 Axis Adv button in the Machining Browser and selecting the Horizontal Roughing Operation.  3 Axis Horizontal Roughing Menu Item |

3 Axis Horizontal Roughing |

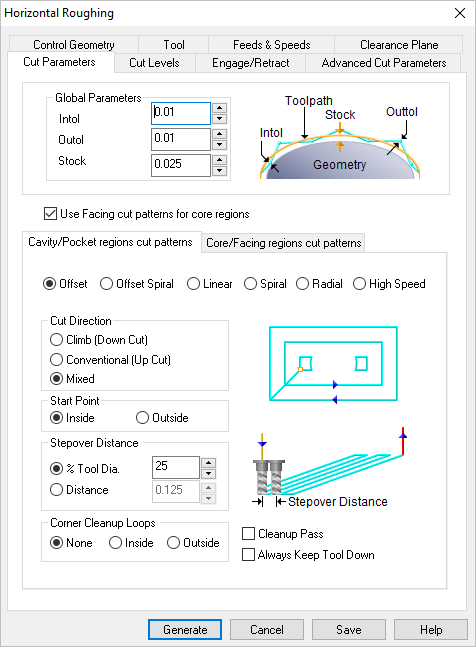

The dialog that is invoked when you choose this toolpath method is shown below:  Dialog Box: 3 Axis Horizontal Roughing Operation |