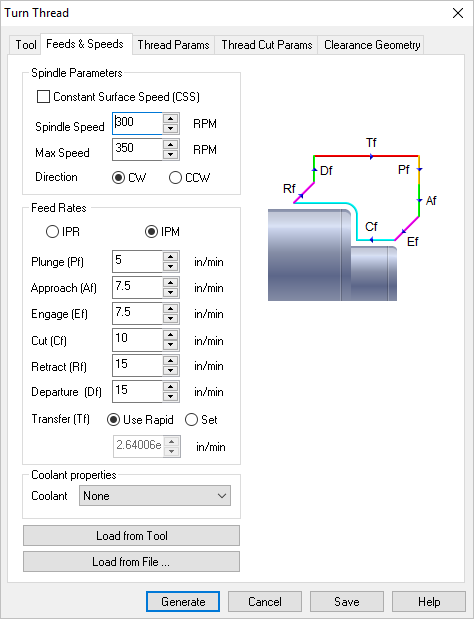

The following dialog allows you to select the appropriate Feeds & Speeds for the Turn Thread operation. In this tab, Spindle Parameters and Feed Rates can be specified. Speeds & Feeds can also be loaded from a File or from the Tool.

Dialog Box: Feeds & Speeds tab, Turn Thread |

Constant Surface Speed (CSS)

This is the Spindle Speed Mode. If this box is checked, the mode is set to Constant Surface Speed (CSS). If unchecked, the mode is set to Constant Rotational Speed (CRS).

If the Constant Surface Speed is checked, the controller would automatically calculate and adjust the spindle speed based on the current diameter of the work-piece. If this calculated spindle speed is greater than the maximum spindle speed specified in your post, the spindle speed would be reduced to the maximum speed. Refer to the Spindle section of the Post-Processor Generator to ensure your Spindle Mode is set correctly.

Spindle Speed

his is the rotational speed of the spindle expressed in RPM.

Surface Speed

Surface speed is set in units/min when Constant Surface Speed is selected. This is only applicable for turning inserts.

Max Speed

The maximum rotational speed of the spindle, in RPM. This is only applicable for turning inserts.

Direction

This determines the direction of spindle rotation and can be set to Clockwise or Counter Clockwise.

|

Feedrate can be set in Units/Min or Units/Revolution for Turning Inserts.

Plunge (Pf)

This rate is the feed before the tool starts to engage in material. This is always vertical.

Approach (Af)

This is the feedrate used that prepares the cutter just before it starts engaging into material as it starts cutting. The approach motions are dependent on the method of machining.

Engage (Ef)

This is the feedrate used when the tool is performing an engage move. TURN Module sets this value to be 75% of the cutting speed.

Cut (Cf)

This is the feedrate used when the tool is cutting material

Retract (Rf)

The feedrate used when the tool is performing a retract move away from material. TURN Module sets this also to also be 75% of the cutting speed.

Departure (Df)

The feedrate used to retract the tool from the material.

Transfer (Tf)

This is the feedrate (in Units/Min), used for Transfer motions. Select Use Rapid to set this to the Transfer Feed value defined in the Feeds & Speeds section of the CAM Preferences dialog.

|

Here you can override the Coolant that is specified by the Tool. Coolant can be set to Flood, Mist or Through. Coolant codes are defined in the post processor generator under Misc tab.

|

Feeds & Speeds are defined when a tool is created using Create/Edit Tools from the Machining Objects Browser. Selecting this button loads the Feeds & Speeds from the tool that is selected for the current machining operation.

|

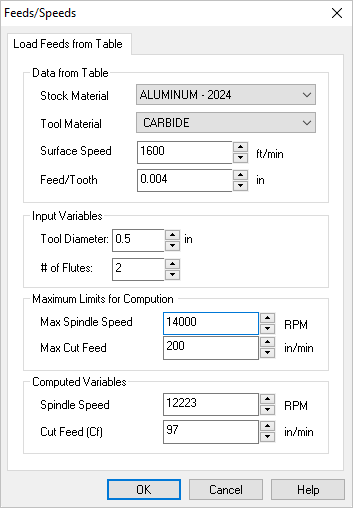

This loads the Feeds & Speeds values from the Feeds & Speeds Table file. This will display the Load Feeds from Table dialog box to make your selections.

Selecting OK from this dialog transfers the spindle speed and cut feedrate to the Feeds & Speeds tab. The plunge, approach, engage, retract and departure feeds are determined using a percent of the cut feed. The percent to use for transferring the computed cut feed can be set under Feeds & Speeds Preferences.

Dialog Box: Load Feeds from Table |

Stock Material

Selecting a Stock Material and Tool Material displays the Surface Speed and Feed/Tooth. This information is contained in a feeds and speeds data file which can be edited to add newer materials.

Tool Material

Selecting a Stock Material and Tool Material displays the Surface Speed and Feed/Tooth. This information is contained in a feeds and speeds data file which can be edited to add newer materials.

Surface Speed

Selecting a Stock Material and Tool Material displays the Surface Speed and Feed/Tooth. This information is contained in a feeds and speeds data file which can be edited to add newer materials.

Feed/Tooth

Selecting a Stock Material and Tool Material displays the Surface Speed and Feed/Tooth. This information is contained in a feeds and speeds data file which can be edited to add newer materials.

|

The input variables - Work Diameter is automatically loaded from the Stock Radius. Based on this parameter and the Variables Limits parameters, the program computes Spindle Speed and Cut Feedrate (Cf). measured in Unites/Revolution. Changing the spindle speed modifies the cut feedrate.

|

Here you can set the Max Spindle Speed and Max Cut Feed (Cf) values. Once these two values are set, the Spindle Speed and Cut Feed calculated by this dialog will not exceed these values even if you attempt to enter higher values into the Computed Variables fields. To exceed these values, change them here or you must edit the operation or tool parameters manually.

|

The variables for Spindle Speed and Cut Feed (Cf) are computed for you based on the selections made in this dialog but will not exceed the values set in the Maximum Limits for Computation section of the dialog. These values are then assigned to the active toolpath operation or tool. You can override either of these variables and the other will update automatically. Since this dialog is a Feeds & Speeds Calculator, you cannot override both values. To do so, you must edit the operation or tool parameters manually.

|

|