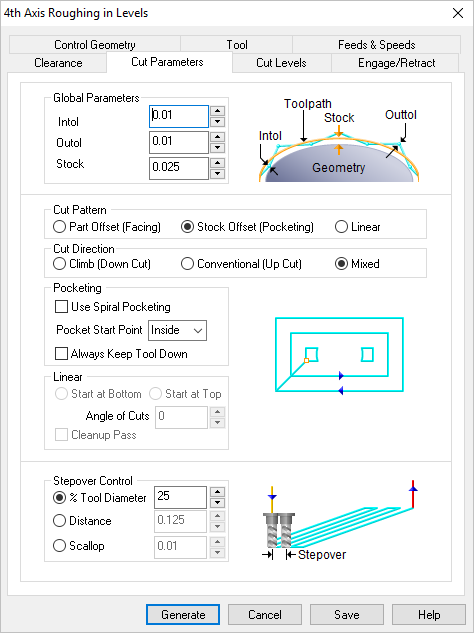

The following Cut Parameters tab allows you to define the cut parameters for the current 4 Axis R-Level Roughing operation. You can set Global Parameters, Cut Direction, and the Cut Containment parameters via this tab of the operation dialog. The Global Parameters section allows you to set the tolerance value to be used in machining. A uniform thickness or stock that needs to be left around the part can also be specified here. Refer to each option below.

Dialog Box: Cut Parameters tab, 4th Axis R-Level Roughing Operations |

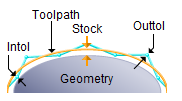

Global Parameters, 3 Axis Operations The Global Parameters section allows you to set the tolerance value to be used in machining. Intol and Outol are allowable deviations (tolerances) from the actual part geometry plus the Stock layer (if any). A uniform thickness or stock that needs to be left around the part can be specified here. Intol / Outol

Stock |

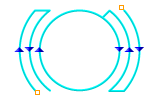

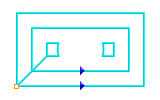

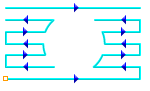

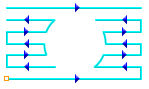

Part Offset (Facing) is a 2D offset facing pattern. The cut regions are successively offset until there is nothing left to machine. This type of cutting is sometimes called spiral machining.  Part Offset (Facing) This is a pocketing pattern derived from the stock geometry.  Stock Offset (Pocketing) Select Linear and the tool will traverse in a Linear cut beginning at the Top or Bottom depending on the Start Point selection.  Linear |

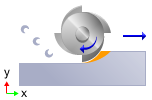

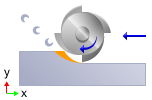

This can be controlled by specifying either Climb (Down Cut), Conventional (Up Cut) or Mixed.

|

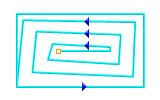

Select Offset Spiral and the tool will traverse in a spiral pattern with successive offsets of the part shape starting from the Inside or Outside depending on the Start Point selection.  Offset Spiral Choose where you want the cut pattern to begin, Inside the pattern or Outside.

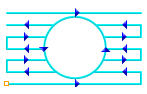

When checked, the system tries, when possible, to keep the cutter in contact with the cut level plane while connecting all areas within a single machining region. Otherwise the cutter will retract and re-engage. |

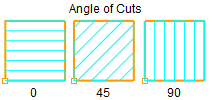

Select this option if you want the starting locating for the cut pattern to begin at the bottom of the cut pattern (i.e., min Y).  Start at Bottom Specify the Angle of Cuts (0-360) measured from the X Axis. This additional parameter is available for some operations when a linear cut pattern is used.

Automatically detect corners that the tool could not reach between cut level and add a toolpath based on the uncut area detected. Either Linear or Offset cut patterns are used in these areas.

|

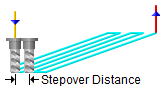

Stepover Control, 3 Axis Operations This allows you to define the spacing between the cuts. Select from the following options: % Tool Diameter Distance Scallop (not available for all operations) |

One of the basic concepts to understand in any milling operation is

One of the basic concepts to understand in any milling operation is