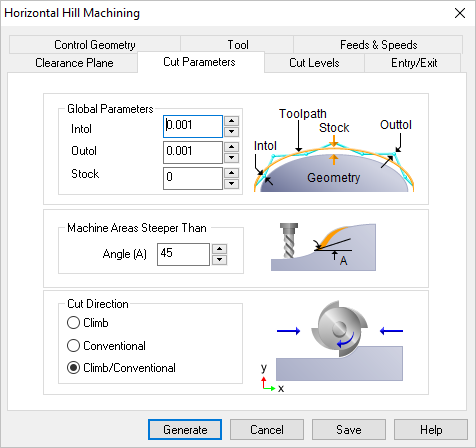

The following Cut Parameters tab allows you to define the cut parameters for the current 3 Axis Steeps Z (Horizontal Hill) Finishing operation. You can set Global Parameters, Machining Area, Cut Direction and the Stepdown Control via this tab of the operation dialog. The Global Parameters section allows you to set the tolerance value to be used in machining. A uniform thickness or stock that needs to be left around the part can also be specified here. Refer to each option below.

Dialog Box: Cut Parameters tab, Steeps Z (Horizontal Hill) Finishing, 3 Axis |

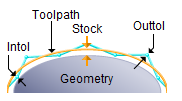

Global Parameters, 3 Axis Operations The Global Parameters section allows you to set the tolerance value to be used in machining. Intol and Outol are allowable deviations (tolerances) from the actual part geometry plus the Stock layer (if any). A uniform thickness or stock that needs to be left around the part can be specified here. Intol / Outol

Stock |

This section allows you to define the Steepness Angle (A). This angle controls which regions will be machined. The system identifies all areas of the part that are steeper than this angle from the horizontal and creates machining regions that are used in the subsequent machining process. |

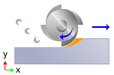

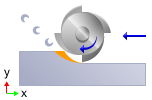

The Cut Direction can be controlled by specifying either Climb (Down Cut), Conventional (Up Cut) or Mixed.

|

This section allows you to define the spacing between the horizontal cut levels for the roughing operation. The spacing can be specified either % Tool Diameter, a specific Distance or as the total Number of Levels desired. |

One of the basic concepts to understand in any milling operation is

One of the basic concepts to understand in any milling operation is