3 Axis Adaptive Roughing

The Adaptive Roughing operation is a high speed bulk material removal toolpath method characterized by its tangential cut (i.e., constant tool engagement) pattern. It reduces tool pressure and keeps chip load more consistent. It is especially valuable when cutting harder materials and generally results in much better tool life. Similar to Horizontal Roughing material is removed in layers or levels from the raw stock model. This is a constant contact toolpath method with just one entry and on exit at each cut level. Typical tools used for this kind of operation are Flat or Corner Radius mills.

|

|

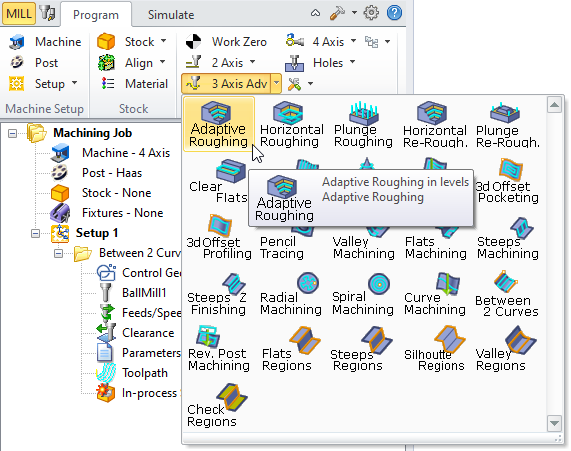

The Adaptive Roughing toolpath method is invoked by selecting the Program tab, clicking on the 3 Axis or 3 Axis Adv button in the Machining Browser and selecting the Adaptive Roughing operation.  3 Axis Adaptive Roughing Menu Item |

|

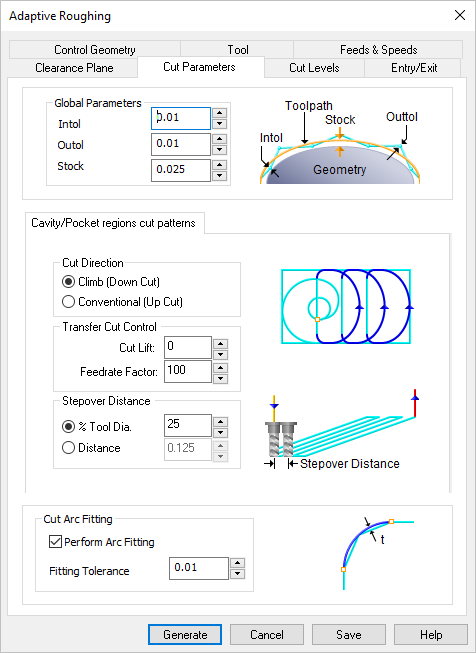

The dialog that is invoked when you choose this toolpath method is shown below:  Dialog Box: 3 Axis Adaptive Roughing Operation |