Available in: |

Xpress |

Standard |

Expert |

Professional |

Premium |

![]()

Surface Normal, 5 Axis

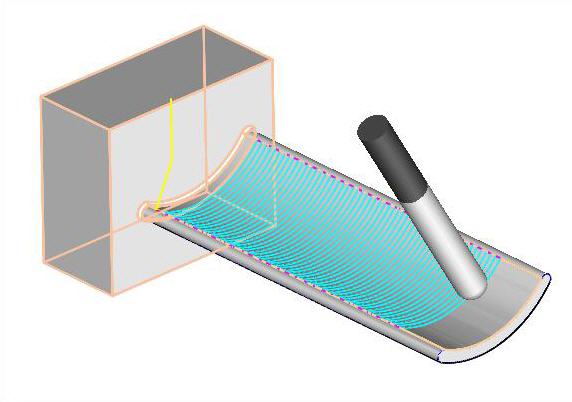

In this type of machining, a single surface or a set of surfaces is selected as drive surfaces and the tool axis is set to be normal to these surfaces. The cut pattern is defined by one or more drive surfaces. The cut pattern can be defined to follow the iso-parametric lines of the drive surface(s). (That is parallel to an edge curve). In this type of machining material is removed using the bottom and/or the corner radius areas of the cutter. This can be considered as “Tool End Cutting”.

This is an efficient method of finishing. A linear pattern is generated. The tool moves along this cut pattern, following the contours of the part geometry below and stays normal to the surface. The cut pattern could be parallel to X, Y, Z or by specifying vertical and horizontal angle.

See also: What Tool Types are Supported by this Operation?

Surface Normal, 5 Axis Example |

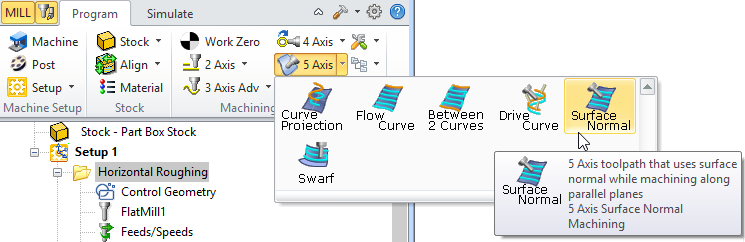

The 5 Axis Surface Normal operation is invoked by selecting the Program tab, clicking on the 5 Axis button in the Machining Browser and selecting the Surface Normal Operation.  Surface Normal, 5 Axis Menu Item - Premium Configuration Shown |

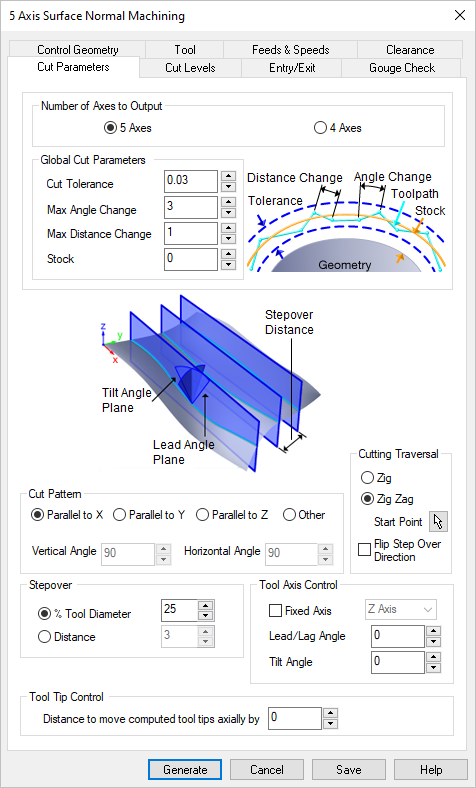

The dialog that is invoked when you choose this toolpath method is shown below:  Dialog Box: Surface Normal Operation, 5 Axis |